INSPECTION SERVICES

(SCOTLAND) LIMITED

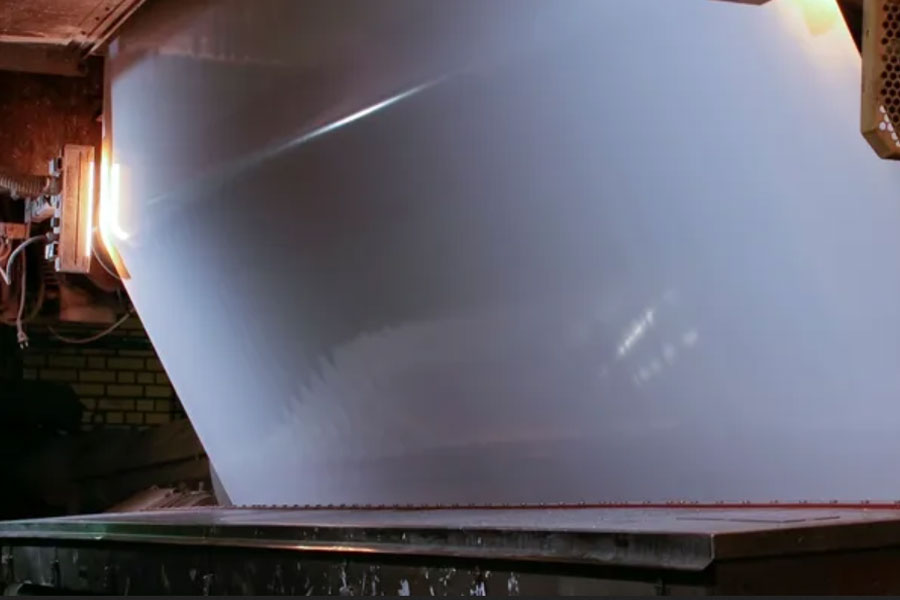

Corrosion Control Inspection

Specifications (ITP/ITR`s) Document reviews

Our inspectors are readily accessible to any location throughout the UK.

We serve a diverse client base, including large civil asset owners and smaller specialist contractors. Our meticulous attention to service and detail has established us as a leader in the paint inspection industry.

Coatings & Insulation Conditioning Surveys

Our inspectors are readily accessible to any location throughout the UK.

We serve a diverse client base, including large civil asset owners and smaller specialist contractors. Our meticulous attention to service and detail has established us as a leader in the paint inspection industry.

Protective Coating Condition Survey is an essential tool for every Asset and Project Managers to obtain valuable information before initiating a works or maintenance program.

Data can be utilised to forecast future maintenance needs,

Our surveys comprehensively assess all the structure’s components, identified as requiring surveying, with consistency and entirety. By establishing the current state of the coating,

we provide recommendations that allow maintenance budgets to be efficiently utilised based on the coating’s condition rather than its age.

Coatings failure Investigation

The application of a protective coating entails various factors, necessitating the expertise of experienced inspectors to identify and determine the root cause of any failures.

The investigation involves collecting data on the coating type, application method, service life, operating environment, and physical properties of the failed coating.

Using this data, Inspection Services Scotland Limited will generate a Technical Report that complies with (Rule 35) Expert Witness standards.

Coating Inspection Certification

At Inspection Services, we take pride in the extensive experience and qualifications of our inspectors.

We provide onsite coverage at NACE L2 & 3 , ICORR Level 2 and BGAS L1 certified paint inspectors, as well as a team of senior inspectors holding high-level certifications who can assist remotely.

Our expertise spans a wide range of sectors, including the Oil & Gas industry, Petro-chemical Rail Network, Local Authorities, Highways Marine, and Renewables projects.

Paint inspection services is crucial for ensuring the quality and longevity of protective coatings on various structures. These services involve thorough examinations of paint applications and identifying detects, inconsistencies, or signs of deterioration.

By conducting detailed Protective Surveys our inspectors can assess the current condition of the coatings, verify compliance with industry standards, and recommend necessary maintenance or repairs.

Pipeline Inspection

We know how important it is to be confident of the integrity of your assets and our comprehensive pipe Inspection Services provides cutting-edge techniques to assess the condition of your pipelines and pipes accurately.

Through a range of inspection techniques, our experienced team of technicians can help you extend the lifetime of your pipeline, save on costly repairs, minimise safety risks, and ensure compliance.

Our services include – Digital radiography pipe inspection. Harnessing the power of digital radiography, we conduct pipe inspections with unparalleled clarity and efficiency. This method allows for real-time imaging of the internal structure of pipes, enabling swift and accurate assessments.

Corrosion mapping – We utilise the latest technology to perform efficient and accurate corrosion mapping pipe and identify areas of corrosion or damage.

We understand the unique challenges faced by industrial pipelines.

Coatings & Insulation Inspections (CUI)

We can assist in evaluating the application of Thermal Insulation and Corrosion Under Insulation and it impact on the substrates.

In the UK, companies spend around £60 billion every year to repair materials and replace infrastructure due to corrosion & Corrosion Under Insulation (CUI) .

There are several factors to consider when applying protective coatings under Insulation and the consequences of ingress of moisture of improper installation of membranes and vapour barriers. This can have catastrophic consequences on the functionality and lifespan of the system. Failures are often due to poor workmanship.

Inspection Services Scotland Limited offers client-experienced inspectors who specialises in quality control inspections.

Intumescent Fire Protection Services

We can support our clients in various ways, ranging from Fire Hazards Zone layouts, documentation review, full or part-time inspections, to complete management of your coating project.

Having one of our experienced PFP inspectors on your team can be invaluable in preventing potential issues from arising, and early detection and intervention, in case any issues arise, can greatly reduce the impact on the program and associated costs.

If existing Intumescent Coatings require verification, one of our inspectors can visit your premises to remove some samples for laboratory verification of coating type and conduct a detailed survey identifying any areas that may require remedial works, along with photographs, upon verification of coating type and completion of any remedials.

Water Utility Sector

We recognise the critical role of well-maintained assets in ensuring efficient utility provision. Preventing leaks is essential to sustaining operational integrity, minimising disruptions for users, and enhancing cost-effectiveness.

We aim to give you the confidence that your pipelines are secure. Within the Water Utility Sector, we offer a comprehensive suite of services including corrosion mapping, leak detection, pipe ovality inspection and soil sampling. With our responsive approach, we ensure a flexible service that helps your projects remain on track.

Lead Paint Surveys

We can support our clients in any work that involves the use of materials containing lead, such as old lead paint coatings, is regulated under the ‘Control of Lead at Work Regulations 2002’.

Inspection Services uses the latest XRF-I non-destructive equipment to conduct comprehensive Lead Surveys of buildings or locations where work is to be carried out that may potentially disturb paint coatings.